how do rivets work diagram

Figure 1 This diagram shows the operating principle of a. Two strips of dissimilar metals are mechanically joined either by rivets or by being fused together along their length to form a structure that responds to changes of temperature by bending in a preferred direction.

Understanding Blind Rivets Fastener Mart

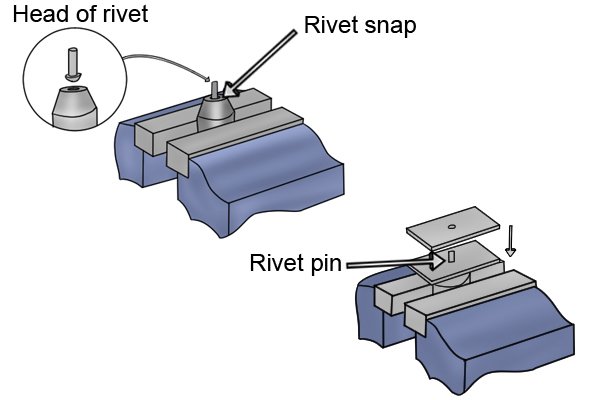

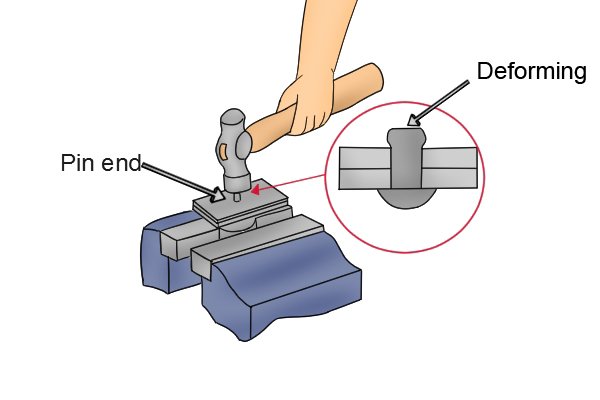

Install a rivet in the skin place the dimple set block on the back side and lightly drive the rivet into the dimple set block.

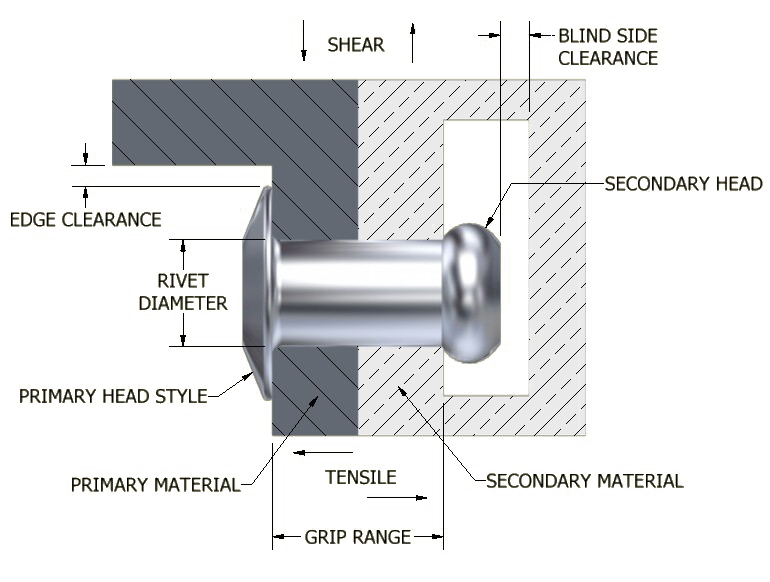

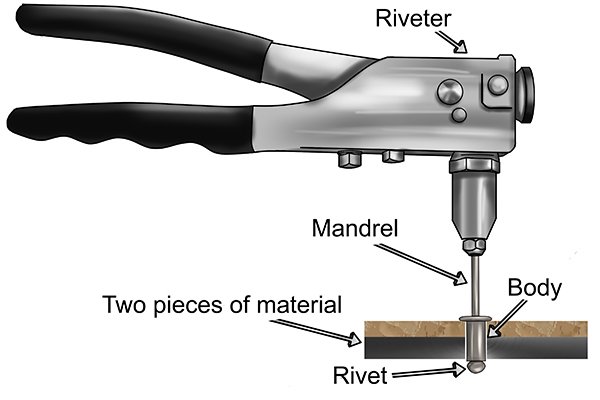

. A rivet is a mechanical fastener with a plane unthreaded shaft thats inserted through holes to join two or more parts together. A open rivet b closed rivet. Position tool with rivet by placing rivet in the hole with flange flush against surface.

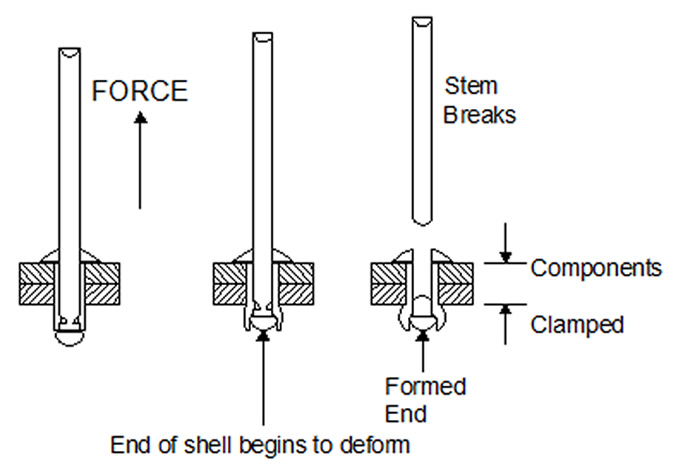

It will form a connection and thus the parts will be joined securely. The mandrel is the portion of the rivet that is pulled into the rivet and mostly removed. Snap head or cup head rivets.

How Do Standard Blind Rivets Work. Insert your rivet into your pre-drilled hole. The nub end of the rivet will be pointing away from the gun.

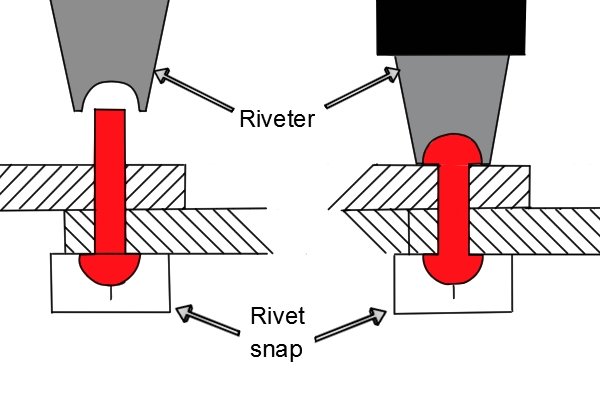

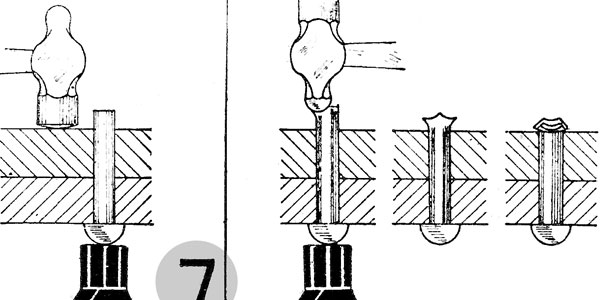

Squeeze handle to pull and cut off excess mandrel and set rivet PIC 3. A standard blind rivet mandrel has a designed flaw near the base of the mandrel. Before being installed a rivet consists of a smooth cylindrical shaft with a head on one end.

With some projects finding a fastener that works with thin or brittle materials can seem impossible. A permanently formed head at each end prevents the rivet from being removed from the hole. The first part is called the rivet body also known as the shell or hat and the second part is called the mandrel also known as the stem.

The head is of a semi-circle in shape. The joints of this rivet are very strong. The quality and method of performing riveting are determined by the manufacturers professionalism and skill.

The hole should be just. The rivet can no longer be pulled through the hole because it is now flared on the underside of the. When you do this it only take two or three taps with the rivet gun at low throttle.

A standard pop rivet mandrel has a designed flaw near the base of the mandrel which makes it easier to snap. The two pieces of plastic or aluminium are drilled to a size slightly larger than the rivet. The rivets are kind of the adjacent surfaces between the two parts to be joined.

This will rivet the two surfaces together by driving the pin into the rivet. On installation the rivet is placed in a punched or drilled hole and the tail is upset or bucked so that it expands to about 15 times the original shaft diameter holding the rivet in place. Whether they are blindpop rivets singledouble capped tubular or solid copperbrass rivets that require a burr to secure them Rivets all work by squeezing layers of material together.

A rivet body is the portion of the rivet that deforms and stays in the installation. The pop rivet is passed through both holes in the sheet plastic aluminium. A pop rivet is then inserted through the drilled hole and the rivet body is brought into contact.

The head should be pushed firmly up against the end of the gun. Identify the long pin of the rivet. Before using it or buying it one must have a crystal clear idea on how does a pneumatic rivet gun work.

Rivets with this kind of heads are used most of all. This type of rivets is shown in the figure. The shaft prevents any radial movements of the components.

Pop rivets consist of two parts. The only difference is that the head of a countersunk rivet is designed in a way that it will become concealed from the surface of the structure once it has been driven in place. If two or more strokes are necessary to set rivet handle must be reopened completely.

Continue reading to learn how and why rivets are such an important part of the leatherworking process. A rivet hat is the portion of the rivet that deforms and stays in the installation. The riveting process can be done for the hollow as well as the solid workpieces.

A pneumatic rivet gun is very popular for its use in bonding metallic pieces. Slide the rivet through the two holes. Insert it into the riveting tool.

The rivet is deformed by pounding or smashing of the tail which makes the material flatter and usually causes the tail to be expanded by about one and a half times the size of the stems original diameter. A rivet is a permanent mechanical fastener. When using the closed rivets on the product it is also important to use appropriate tools and equipment.

The rivet pliers are pushed on to the pin of the rivet and the handles are pulled together. The mandrel is the portion of the rivet that is pulled into the rivet and mostly removed. Obverse and reverse side.

Firmly press your rivet into the pre-drilled hole with the nub completely clearing the hole. When finished the tail has the appearance of. Two strips of dissimilar metals are mechanically joined either by rivets or by being fused together along their length to form a structure that responds to changes of temperature by bending in a preferred direction.

The end opposite to the head is called the tail. This will cause the rivet to expand. How do Rivets Work.

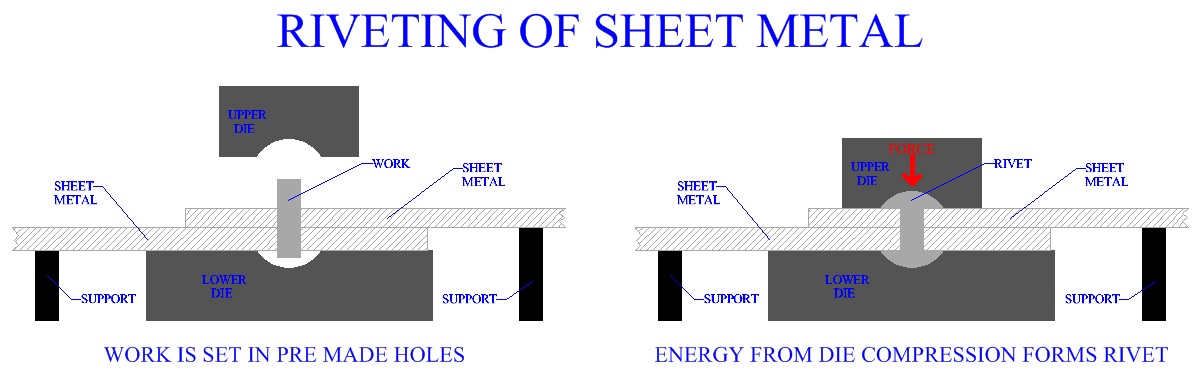

In situations where access to both sides of a component is limited a hole is first drilled through the parts to be joined. When installed the rivet is either drilled placed or punched into a hole afterwards the tail is then deformed holding the rivet in place. Figure 1 This diagram shows the operating principle of a.

Its diameter is 16D and its height is 07D. Blind rivets are comprised of two parts. A rivet is a visible part of the product.

Take your rivet tool and squeeze its handles together. This draws all of the parts tightly together and makes the rivet tight in. The blind rivet gets inserted into the riveting gun via the mandrel.

The body and the mandrel. That is why it is widely used in bridges made of iron material. Countersunk rivets work very similarly to a standard rivet in that they both require access from both sides of the structure.

This is where rivet nuts which are also known as a blind nuts blind rivet nuts or threaded inserts come inA variation on the standard rivet the rivet nut has a tubular round splined square or hexagonal body that is internally threaded and counterbored. Move rivet tool down against flange of rivet so that nosepiece is again. A straight metal piece will be inserted via the hole or cavity provided for the two materials to be joined.

Being a useful tool it is now widely used in construction projects transportation industries aerospace manufacturing and many others. To install a rivet first a hole needs to be drilled into the two materials. This will set the aluminum and the rivet tight and flush.

How Does A Solid Rivet Work Wonkee Donkee Tools

Riveted Joints Definition Applications Operations Types Studentlesson

Schematic Diagram Of Friction Self Piercing Riveting Process A Rivet Download Scientific Diagram

What Is A Rivet How Is Riveting Done Riveting Definition Types Of Rivet

What Are Structural Rivets Albany County Fasteners

Pop Rivet Selection Factors Stanley Engineered Fastening

What Is Rivet Definition Types Working Process Engineering Choice

About Making And The Use Of Rivets Small Farmer S Journal

Marson Blind Rivets How Blind Rivets Work Bolt Products Inc

Automotive Rivets Explained Henry S Automotive Warehouse

How Does A Blind Rivet Work Wonkee Donkee Tools

How Does A Solid Rivet Work Wonkee Donkee Tools

How Do Rivets Work Fastener Engineering

Benefits Of High Strength Structural Rivets Goebel Fasteners

What Is Pop Rivet Types And How Do They Work Engineering Choice